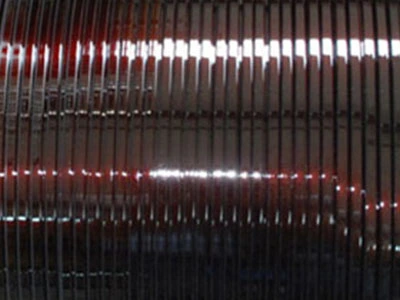

Insulating Material: The conductor shall be coated with a dual film. The underlying coating is based on polyester (amide)(imide) resins. The superimposed coating is based on polyamideimide resins.

Dimension:

Film-Insulated Rectangular Magnet Wire Increase in Thickness and Width Due to Film Coating

| Build | Increase in Width | Increase in Thickness | ||||||

| Minimum | Maximum* | Minimum | Maximum* | |||||

| inches | mm | inches | mm | inches | mm | inches | mm | |

| Heavy | 0.0025 | 0.064 | 0.0045 | 0.114 | 0.0030 | 0.076 | 0.0050 | 0.127 |

| Quad | 0.0040 | 0.102 | 0.0060 | 0.152 | 0.0050 | 0.127 | 0.0070 | 0.178 |

Adherence And Flexibility: No cracks visible in the film coating

Elongation:

| Wire Size | Bare or Film- Insulated | |

| MW Specification | 18, 36, 64 | |

| Square andRectangular | T ≥0.049” | 15 |

| T < 0.049” | 15 | |

Heat Shock: No cracks visible in the film coating after 10% elongation followed by conditioning at 240ºC

Dielectric Breakdown: Applicable to Heavy film-insulated sizes having a thickness of less than 1.25 mm or a width greater than 12.5 mm, or a width-to- thickness ratio greater than 5:1, and all Quad.

| Film Insulation | Minimum Breakdown Voltage | |

| Any Three of Four Values | Fourth Value | |

| Heavy | 1500 | 500 |

| Quad | 2500 | 900 |

The combination of Class 220-rated polyester with amide and imide components, overcoated with polyamideimide, provides a robust and reliable solution for various electrical and industrial uses.