Copper and aluminum are two materials widely used in power and electrical engineering, each with its unique performance characteristics.

Here are 10 key differences between copper and aluminum in terms of conductivity:

Conductivity: Copper has higher conductivity than aluminum, approximately 1.5 times that of aluminum. This means that under the same conditions, copper wires have lower resistance and less energy loss.

Resistivity: Copper has lower resistivity than aluminum, making copper wires more efficient in transmitting power and reducing energy loss.

Mechanical Strength: Copper wires have higher tensile strength and better flexibility, making them more reliable in installation and long-term use.

Durability: Copper wires have superior durability and corrosion resistance compared to aluminum wires. In harsh environments, copper’s stable performance helps reduce maintenance costs.

Weight: Aluminum wires are lighter than copper wires, making them more advantageous in applications where weight reduction is crucial, such as in overhead power lines.

Installation and Connection: The flexibility of copper wires makes them easier to install and connect, while aluminum wires may require special connection techniques and materials to prevent corrosion.

Long-term Cost: Although copper has a higher initial cost, its lower long-term maintenance and energy loss may make copper wires more cost-effective over time.

Environmental Impact: The mining and smelting of copper have a larger environmental impact, but copper is highly recyclable, helping to reduce its environmental footprint.

Flexibility: Copper has more flexible and less likely to break when bent, making it easier to work with in installations.

Thermal Expansion: Aluminum has a higher thermal expansion rate than copper, which can affect connection stability, especially in environments with significant temperature fluctuations.

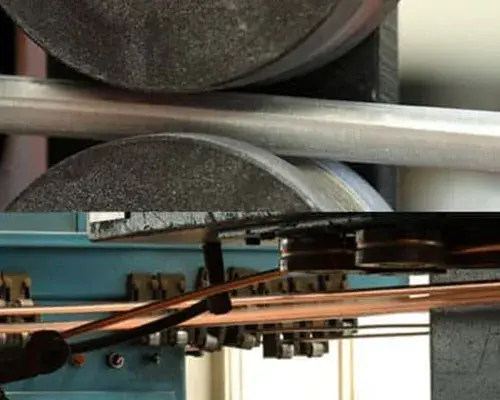

Application Range: Due to its superior conductivity and reliability, copper wire is typically used in residential, commercial, power transformers and high-performance electronics and industrial power systems, while aluminum wire is often used in high-voltage transmission lines and applications where weight reduction is essential.

When choosing between copper and aluminum wire, it is important to consider the specific needs of the project, cost budget, installation environment, and long-term maintenance to ensure the efficiency and reliability of the power system.