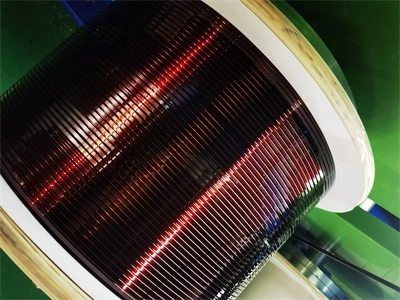

Polyester (Amide)(Imide) Overcoated with Polyamideimide Film-Insulated Square Copper Magnet Wire Thermal Class 220. The Square shape reduces winding spaces and enhances coil density, optimizing the performance of electrical equipment.

Table 1 Specifications

| Insulation materials | Film – lnsulation Types Polyester Overcoated with Polyamideimide; Polyester (lmide) Overcoated with Polyamideimide; Polyester (Amide) Overcoated with Polyamideimide |

| Thermal Class | 220 |

| Dimensions | Square: 1-14 AWG Bare conductor:1.628mm-7.328mm Heavy:1.781mm-7.549mm Quad:1.831mm-7.60mm |

| Certificate | MW 38-C |

| Insulation thickness | Heavy and Quad |

Table 2 Periodic conformance tests

| Thermoplastic flow | Median not less than 325ºC when tested as MW 37-C Heavy Build |

| Solubility | Specimens immersed in xylene and 50/50 xylene/butyl Cellosolve shall not soften sufficiently to expose the bare conductor |

| Dielectric breakdown rated temperature | Average not less than 75% of the value required at room temperature, when tested on MW 35-C Heavy build |

Table 3 Properties

| Adherence and flexibility | No cracks visible in the film coating |

| Elongation | Bare or Film- Insulated MW Specification 18, 20, 36, 38, 64, 84 |

| Heat shock | No cracks visible in the film coating after 15% elongation followed by conditioning at 240ºC |

| Springback | Not greater than 5º |

| Dielectric breakdown | Not less than the value in Heavy (500-1500) / Quad (900-2500) Applicable to Heavy film-insulated sizes having a thickness of less than 0.049 in. (1.25 mm) or a width greater than 0.492 in. (12.5 mm), or a width-to- thickness ratio greater than 5:1, and all Quad. Other Heavy film-insulated sizes shall be tested in accordance with Foil Electrode Method Heavy film-insulated sizes having a thickness 0.049 in. (1.25 mm) or greater; a width of 0.492 in. (12.5 mm) or less; and a width-to-thickness ratio not more than 5:1 shall have a dielectric breakdown voltage not less than in the table above after bending |