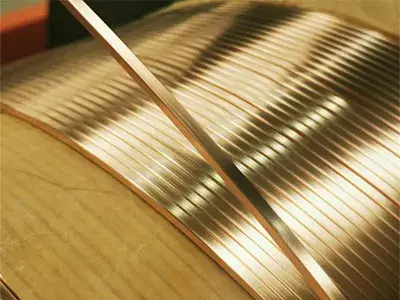

240 grade polyimide film insulated square copper magnet wire is a high-performance magnet wire material that can prevent the insulation damage or performance degradation of the magnet wire due to high temperature; it is suitable for aerospace, automotive industry, power electronic equipment, etc.

Characteristic

| Adhesion and Flexibility | No visible cracks on the film coating |

| Elongation | MW specification: not less than 18, 20, 36, 38, 64, 84T≥0.049:32 T<0.049:30 |

| Thermal Shock | No cracks on the film coating after 15% elongation and conditioning at 280°C ±3ºC |

| Rebound | not more than 5° |

| Dielectric Breakdown | Square magnet wire Heavy duty: not less than 500v-1500v Type IV: not less than 900v-2500v |

| Dissipation Factor | not more than 0.60% |

Regular compliance testing

| Thermoplastic Flow | Mean value not less than 450°C |

| Solubility | Samples immersed in xylene and 50/50 xylene/butyl cellosolve shall not soften enough to expose bare conductors |

| Dielectric Breakdown at Rated Temperature | Mean value not less than 75% of the value required at room temperature |

| Square AWG Size | 1-14AWG | |

| Bare wire size | Minimum | 1.603mm-7.275mm |

| Nominal | 1.628mm-7.348mm | |

| Maximum | 1.654mm-7.422mm | |

| Radii (±25%) Nominal | 0.40±25%-1.0±25% | |

| Heavy | Minimum increase | 0.080mm |

| Maximum population | 1.781mm-7.549mm | |

| Quadruple | Minimum increase | 0.127mm |

| Maximum population | 1.0831mm-7.600mm | |