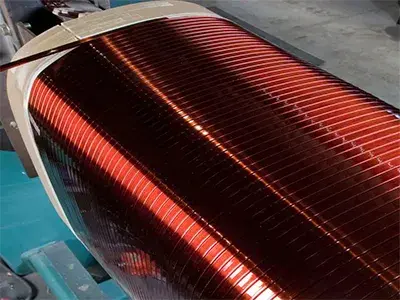

Class 240 grade polyimide film insulated flat copper magnet wire has high temperature resistance and can maintain good insulation performance in high temperature environment. It is suitable for electrical equipment and electronic components.

Film-Insulated Rectangular Magnet Wire Increase in Thickness and Width Due to Film Coating

| Build | Increase in Width | Increase in Thickness | ||||||

| Minimum | Maximum* | Minimum | Maximum* | |||||

| inches | mm | inches | mm | inches | mm | inches | mm | |

| Heavy | 0.0025 | 0.064 | 0.0045 | 0.114 | 0.0030 | 0.076 | 0.0050 | 0.127 |

| Quad | 0.0040 | 0.102 | 0.0060 | 0.152 | 0.0050 | 0.127 | 0.0070 | 0.178 |

Characteristic

| Adhesion and Flexibility | No visible cracks in film coating |

| Elongation | MW Specification: not less than 18, 20, 36, 38,64, 84 T ≥0.049:32 T < 0.049: 30 |

| Thermal Shock | No cracks in film coating after 15% elongation, conditioned at 280°C ±3ºC |

| Rebound | Not greater than 5° |

| Dielectric Breakdown | Film Insulated Rectangular and Square Magnet WireHeavy duty: not less than 500v-1500v Quad: not less than 900v-2500v |

| Dissipation factor | not more than 0.60% |

Regular compliance testing

| Thermoplastic Flow | Mean value not less than 450°C |

| Solubility | Samples immersed in xylene and 50/50 xylene/butyl cellosolve shall not soften enough to expose bare conductors |

| Dielectric Breakdown at Rated Temperature | Mean value not less than 75% of the value required at room temperature |