Wire Types

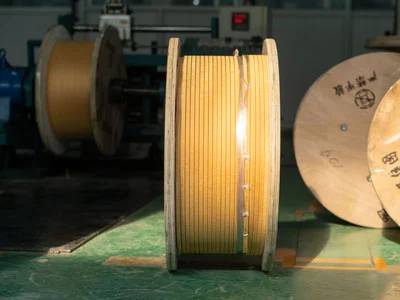

Class 180 Glass Fiber Covered High-Temperature Organic Varnish Treated Bare Rectangular Copper Magnet Wire

Class 180 Glass Fiber Covered High-Temperature Organic Varnish Treated Film-Insulated Rectangular Copper Magnet Wire

Class 180 Glass Fiber Covered Bare Rectangular Copper Magnet Wire

Class 180 Glass Fiber Covered Film-Insulated Rectangular Copper Magnet Wire

Class 180 Glass Fiber Covered High-Temperature Rectangular Copper Magnet Wire

Insulating Material

The glass fiber shall be electrical-grade continuous-filament glass yarn. If underlying film insulation is used, it shall have at least a class 155 rating and comply with the applicable specification of Glass Fiber Covered High-Temperature Rectangular Copper Magnet Wire. The glass fiber covering shall be wrapped firmly, closely, evenly, and continuously around the wire. The glass fiber covering shall be treated with a high- temperature non-silicone insulating varnish.

Thermal Class

180

Conductor

Rectangular Copper Magnet Wire

Dimensions

Table1 Increase in Dimensions for Glass Fiber Covered Rectangular Magnet Wire

| Nominal Width of Conductor (Inches) | Increase in Dimensions (Inches) | ||||||||||||||||||

| Glass Fiber Covering Over Rectangular Bare Copper Conductor | Glass Fiber Covering Over Heavy Enameled Rectangular Wire | Glass Fiber Covering OverQuad Build Enameled Rectangular Wire | |||||||||||||||||

| Single CoveringGlass Fiber | Double CoveringGlass Fiber | Single Covering Heavy Film + Single Glass | Double Covering Heavy Film + Double Glass | Single Covering Quad Film + Single Glass | Double Covering Quad Film + Double Glass | ||||||||||||||

| Over | Up To and Incl. | Min. | Nom. | Max. | Min. | Nom. | Max. | Min. | Nom. | Max. | Min. | Nom. | Max. | Min. | Nom. | Max. | Min. | Nom. | Max. |

| – | 0.102 | 0.0050 | 0.0060 | 0.0070 | 0.0080 | 0.0100 | 0.0120 | 0.0080 | 0.0100 | 0.0120 | 0.0110 | 0.0140 | 0.0170 | 0.0100 | 0.0120 | 0.0140 | 0.0130 | 0.0160 | 0.0190 |

| 0.102 | 0.162 | 0.0060 | 0.0070 | 0.0080 | 0.0090 | 0.0110 | 0.0130 | 0.0090 | 0.0110 | 0.0130 | 0.0120 | 0.0150 | 0.0180 | 0.0110 | 0.0130 | 0.0150 | 0.0140 | 0.0170 | 0.0200 |

| 0.162 | 0.182 | 0.0070 | 0.0080 | 0.0090 | 0.0100 | 0.0120 | 0.0140 | 0.0100 | 0.0120 | 0.0140 | 0.0130 | 0.0160 | 0.0190 | 0.0120 | 0.0140 | 0.0160 | 0.0150 | 0.0180 | 0.0210 |

| 0.183 | 0.229 | 0.0070 | 0.0080 | 0.0090 | 0.0110 | 0.0130 | 0.0150 | 0.0100 | 0.0120 | 0.0140 | 0.0140 | 0.0170 | 0.0200 | 0.0120 | 0.0140 | 0.0160 | 0.0160 | 0.0190 | 0.0220 |

| 0.230 | 0.289 | 0.0080 | 0.0090 | 0.0100 | 0.0110 | 0.0135 | 0.0160 | 0.0110 | 0.0130 | 0.0150 | 0.0140 | 0.0175 | 0.0210 | 0.0130 | 0.0150 | 0.0170 | 0.0160 | 0.0195 | 0.0230 |

| 0.289 | 0.344 | 0.0080 | 0.0090 | 0.0100 | 0.0120 | 0.0145 | 0.0170 | 0.0110 | 0.0130 | 0.0150 | 0.0150 | 0.0185 | 0.0220 | 0.0130 | 0.0150 | 0.0170 | 0.0170 | 0.0205 | 0.0240 |

| 0.344 | 0.517 | 0.0080 | 0.0095 | 0.0110 | 0.0130 | 0.0160 | 0.0190 | 0.0110 | 0.0135 | 0.0160 | 0.0160 | 0.0200 | 0.0240 | 0.0130 | 0.0155 | 0.0180 | 0.0180 | 0.0220 | 0.0260 |

General Requirements

| Properties | Requirement |

| DIMENSIONS | Rectangular Wire:Radii in accordance with 0.51-0.99mm (±25%)Thickness tolerances in accordance 1.016-7.341mmWidth tolerances in accordance with 2.057-16.535mmDimensions and increase in thickness in accordance with Table1 |

| ADHERENCE AND FLEXIBILITY | Single or Double with underlying film: no cracks visible in the film insulation after 20% elongation. Examine with normal vision and without removing the glass fiber covering. Double without underlying film: not less than 75 V/mil (2950 V/mm) of minimum thickness of the polyester glass fiber covering on one side |

| ELONGATION | Not less than 32% for a thickness of 0.049 in. (1.25 mm) and greater, or 30% for a thickness of less than 0.049 in. (1.25 mm) |

| SPRINGBACK | Glass fiber covered bare: not greater than 5ºGlass fiber covered Heavy film-insulated: not greater than 5.5º |

| DIELECTRIC BREAKDOWN | Not less than 90 V/mil (3543 V/mm) of the minimum thickness of the glass fiber covering on one side plus the minimum breakdown given in Table2 for the film-insulated wire, if applicable NOTE—The minimum thickness of the glass fiber covering is 35% of the maxi-mum increase in dimensions calculated from: Single: rectangular: Table1Double: rectangular without underlying film: Table1 |

Table2 Dielectric Breakdown, Film-Insulated Rectangular Magnet Wire

| Film Insulation | Minimum Breakdown Voltage | |

| Any Three of Four Values | Fourth Value | |

| Heavy | 1500 | 500 |

| Quad | 2500 | 900 |