Types

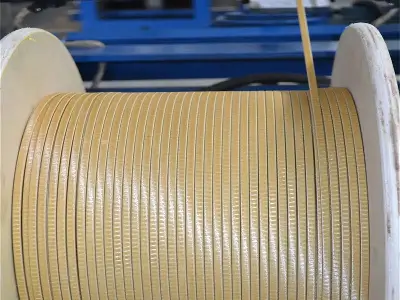

Glass Fiber Covered Silicone Treated Bare Film-Insulated Rectangular Copper Magnet Wire Thermal Class 200

Glass Fiber Covered Silicone Treated Heavy Rectangular Copper Magnet Wire Thermal Class 200

If an underlying film coating is used, it shall have at least a class 180 rating. The glass fiber covering shall be wrapped firmly, closely, evenly, and continuously around the wire.

The glass fiber covering shall be treated with a modified silicone insulating varnish or silicone compound to provide a tough outer finish. If a tracer is used, one or more ends of glass yarn shall be black or green, and the dye or pigment used for this purpose shall be sufficiently stable so as to retain its color identity after the silicone treatment and subsequent baking.

Specifications

Dimensions and increase in thickness in accordance with:

| Glass Fiber Covering Over Heavy Enameled Rectangular Wire* | Glass Fiber Covering OverQuad Build Enameled Rectangular Wire* | ||||||||||

| Single Covering Heavy Film + Single Glass | Double Covering Heavy Film + Double Glass | Single Covering Quad Film + Single Glass | Double Covering Quad Film + Double Glass | ||||||||

| Min. | Nom. | Max. | Min. | Nom. | Max. | Min. | Nom. | Max. | Min. | Nom. | Max. |

| 0.0080 | 0.0100 | 0.0120 | 0.0110 | 0.0140 | 0.0170 | 0.0100 | 0.0120 | 0.0140 | 0.0130 | 0.0160 | 0.0190 |

| 0.0090 | 0.0110 | 0.0130 | 0.0120 | 0.0150 | 0.0180 | 0.0110 | 0.0130 | 0.0150 | 0.0140 | 0.0170 | 0.0200 |

| 0.0100 | 0.0120 | 0.0140 | 0.0130 | 0.0160 | 0.0190 | 0.0120 | 0.0140 | 0.0160 | 0.0150 | 0.0180 | 0.0210 |

| 0.0100 | 0.0120 | 0.0140 | 0.0140 | 0.0170 | 0.0200 | 0.0120 | 0.0140 | 0.0160 | 0.0160 | 0.0190 | 0.0220 |

| 0.0110 | 0.0130 | 0.0150 | 0.0140 | 0.0175 | 0.0210 | 0.0130 | 0.0150 | 0.0170 | 0.0160 | 0.0195 | 0.0230 |

| 0.0110 | 0.0130 | 0.0150 | 0.0150 | 0.0185 | 0.0220 | 0.0130 | 0.0150 | 0.0170 | 0.0170 | 0.0205 | 0.0240 |

| 0.0110 | 0.0135 | 0.0160 | 0.0160 | 0.0200 | 0.0240 | 0.0130 | 0.0155 | 0.0180 | 0.0180 | 0.0220 | 0.0260 |

Properties